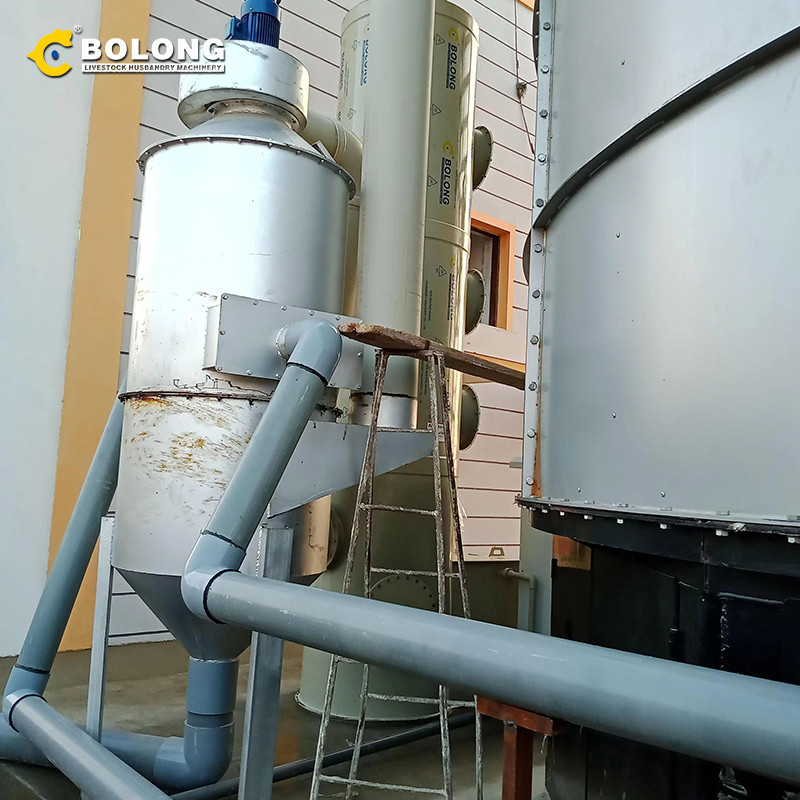

2024/1/1/ · Fermenter/digester: The digester is generally insulated and made of concrete or steel. The large fermenter has an elongated channel shape to optimize the substrate flow, and the large fermenters are generally driven by rotating blades that rotate slowly or rotors. After the aerobic digestion process has stabilized, the pH of the