2021/11/28/ · CONCLUSION Fungal infestation was associated with poor fermentation and hygienic quality of corn silage, adding Hex accelerated the pH decline and maintained the antifungal activity until 90 d of

2021/11/28/ · CONCLUSION Fungal infestation was associated with poor fermentation and hygienic quality of corn silage, adding Hex accelerated the pH decline and maintained the antifungal activity until 90 d of

2016/11/1/ · The TPCSTR system included two phases, thermal (70 °C) pretreatment and mesophilic (37 °C) fermentation (as shown in Fig. 1), and the operating condition of the TPCSTR system is intermittent feeding, that is the feeding material/digested sludge were added/discharged at a certain time every day, respectively.In the first thermal

2017/8/22/ · Mechanistic models require a significant investment of time and resources, but their application to multiple stages of fermentation process development and operation can make this investment highly valuable. This Opinion article discusses how an established fermentation model may be adapted for application to different stages of fermentation

2010/9/1/ · The microbial ecology of meat fermentation is a complex process in which lactic acid bacteria (LAB) and coagulase-negative cocci play a major role. The present work reviews the most significant developments in which LAB are the main characters acting both as starter cultures improving the sensorial quality and as biopreservative agents. New

T1 - Hygiene requirements in the fermentation process. AU - Virkajärvi, Ilkka. PY - 2003. Y1 - 2003. N2 - Although modern control systems have made sterilisation of fermenters and fermentation media in a small scale very easy, understanding the system design may well help in finding the cause when problems arise.

BACKGROUNDThis study aims to reveal the effects of hexanoic acid on the microbial communities, fermentation, and the hygienic quality of corn silages with or without fungal infection. Fungal-infested (FI) and non-infested (NFI) whole-crop corn samples were separately ensiled without (control, CON) or with hexanoic acid (Hex, 90% purity) at 0.2

Biogenic amines are produced by bacterial decarboxylation of corresponding amino acids in foods. Concentration of biogenic amines in fermented food products is affected by several factors in the manufacturing process, including hygienic of raw materials, microbial composition, fermentation condition, and the duration of fermentation. Intake of low

2023/11/28/ · The fermentation process is an essential metabolic process converting carbohydrates into acids, gases, and alcohol, resulting in the conversion of raw meat to

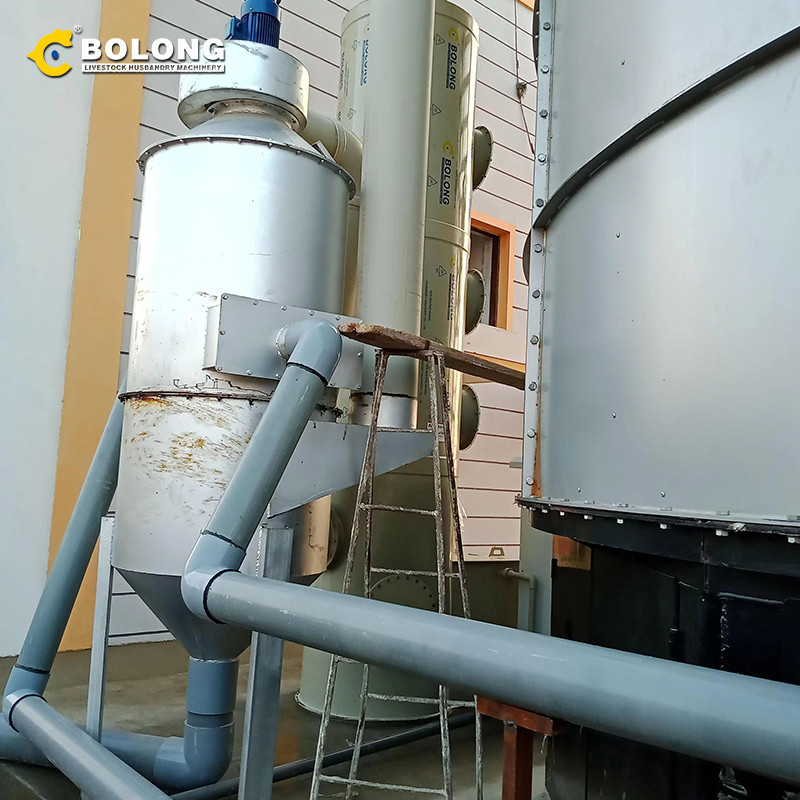

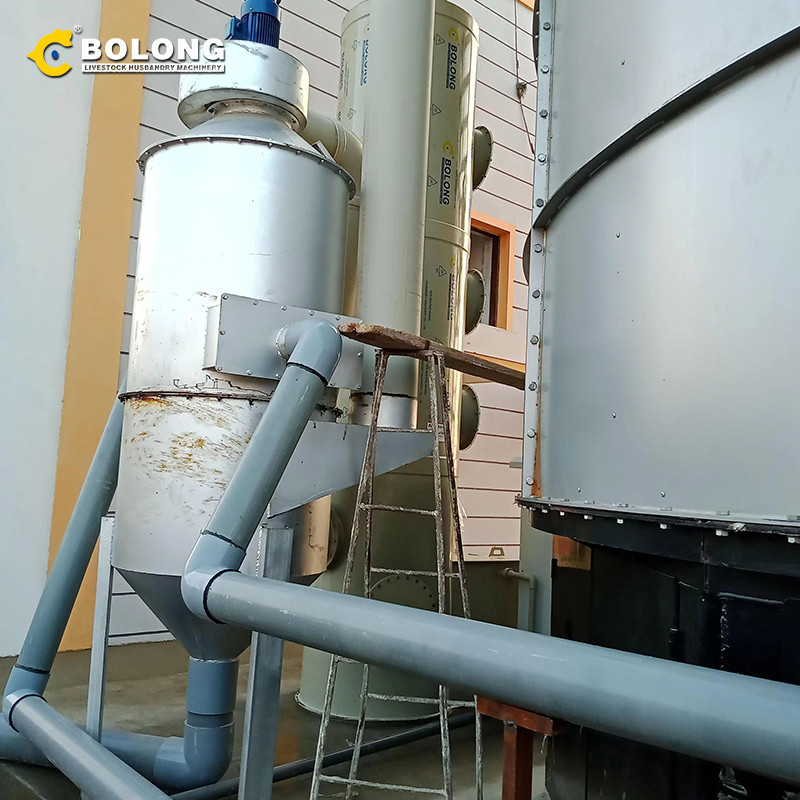

2022/7/20/ · A glycol system can cool a greater volume of liquid in a shorter time. By pumping glycol through coils or pipes in fermentation tanks, the excess heat from the tank transfers into the glycol from the vessel’s contents. The control of temperatures allows for natural yeast fermentation at the correct temperature for that product.

2022/6/1/ · So-called “clean” ball valve designs are available for sizes 6 in. and less. For larger sizes, hygienic butterfly-valve designs should be considered. The tie-in point between the CIP system and the process should be either a block-and-bleed connection, or a line break. Instrumentation.

2023/12/5/ · The objective of the meeting was to evaluate the food safety issues associated with plant-based food products, new applications of precision fermentation, and 3D food printing, as well as to illustrate, through a foresight exercise, the possible future landscape of new foods and production systems. As explained by experts from FAO’s

2022/1/1/ · These contaminations can be introduced to the system in many ways, from the substrate used for fermentation to the facility or staff hygienic factors. Similarly, fermentation modes such repeated batch or continuous normally increase the risk of contamination. Various sterilization techniques are used to minimize contamination.

Section Information. The section Fermentation Process Design of Fermentation aims to rapidly publish contributions on original research, reviews, and short communications on aspects such as novel bioreactor or bioprocess designs, improved separation for recovery of fermentation products, tools for improved monitoring and control of

2023/5/4/ · Plastic Fermenting Tanks. Plastic fermenters are the most affordable option, with prices starting as low as $20 for a basic, small-capacity bucket-style fermenter. Larger plastic fermenters, including conical designs and those with additional features like spigots, can range from $50 to $200.